As a designer, we are inherently interested in venturing into new arenas of product development/design for any number of reasons. David Whetstone is doing his part to develop his portfolio by doing independent research and development for Taylor Made golf bags. His sketches are fun and playful while being informative. This kind of initiative is what employers look for in employees. If you are interested in entering an area of design in which you are not familiar with, I suggest you do what David has done. Don't let others dictate your future to you, build your portfolio around your talents/skills/interests and send it off to those who can give you feedback so that you may achieve your dreams of being a transportation designer/soft goods designer/or whatever. All you have to fear is failure, a trait product development professional are all to familiar with. Who knows, you may be able to bring a new perspective to an industry that is yearning for change.

As a designer, we are inherently interested in venturing into new arenas of product development/design for any number of reasons. David Whetstone is doing his part to develop his portfolio by doing independent research and development for Taylor Made golf bags. His sketches are fun and playful while being informative. This kind of initiative is what employers look for in employees. If you are interested in entering an area of design in which you are not familiar with, I suggest you do what David has done. Don't let others dictate your future to you, build your portfolio around your talents/skills/interests and send it off to those who can give you feedback so that you may achieve your dreams of being a transportation designer/soft goods designer/or whatever. All you have to fear is failure, a trait product development professional are all to familiar with. Who knows, you may be able to bring a new perspective to an industry that is yearning for change.::::::: Design Exposed™ :::::::

Bringing you insight into the processes and imaginations of those who develop and design products™

Wednesday, June 17, 2009

Round Out Your Portfolio - Build Your Tool Box

As a designer, we are inherently interested in venturing into new arenas of product development/design for any number of reasons. David Whetstone is doing his part to develop his portfolio by doing independent research and development for Taylor Made golf bags. His sketches are fun and playful while being informative. This kind of initiative is what employers look for in employees. If you are interested in entering an area of design in which you are not familiar with, I suggest you do what David has done. Don't let others dictate your future to you, build your portfolio around your talents/skills/interests and send it off to those who can give you feedback so that you may achieve your dreams of being a transportation designer/soft goods designer/or whatever. All you have to fear is failure, a trait product development professional are all to familiar with. Who knows, you may be able to bring a new perspective to an industry that is yearning for change.

As a designer, we are inherently interested in venturing into new arenas of product development/design for any number of reasons. David Whetstone is doing his part to develop his portfolio by doing independent research and development for Taylor Made golf bags. His sketches are fun and playful while being informative. This kind of initiative is what employers look for in employees. If you are interested in entering an area of design in which you are not familiar with, I suggest you do what David has done. Don't let others dictate your future to you, build your portfolio around your talents/skills/interests and send it off to those who can give you feedback so that you may achieve your dreams of being a transportation designer/soft goods designer/or whatever. All you have to fear is failure, a trait product development professional are all to familiar with. Who knows, you may be able to bring a new perspective to an industry that is yearning for change.Monday, June 15, 2009

Concept Exploration Using an Underlay - Gatorade Packaging

What is an underlay? Why do designers use them? How can I use an underlay to develop solid solutions for my client? Christopher Lavelanet, an independent contract designer who travels between the US and the EU, has utilized underlays to easy overcome the spacial and volumetric hurdles designers sometimes face when developing design solutions. An underlay is a reference image used by designers to eliminate the need to redefine overall proportion each time they begin to develop a new concept. In the example shown above, the underlay is a simple line drawing, probably taken from a 3D cad drawing, the defines the volumetric considerations the designer needs to stay within as he develops his solutions. He then places another piece of paper, perhaps vellum, tracing paper, graphics 360, etc. on top of the line drawing and uses it as a reference for his design explorations. Underlays also serve to eliminate the need for the designer to redefine the perspective, scale, and proportions that are more easily tackled by using an underlay. This is only a tool used by designers to speed up their process.

What is an underlay? Why do designers use them? How can I use an underlay to develop solid solutions for my client? Christopher Lavelanet, an independent contract designer who travels between the US and the EU, has utilized underlays to easy overcome the spacial and volumetric hurdles designers sometimes face when developing design solutions. An underlay is a reference image used by designers to eliminate the need to redefine overall proportion each time they begin to develop a new concept. In the example shown above, the underlay is a simple line drawing, probably taken from a 3D cad drawing, the defines the volumetric considerations the designer needs to stay within as he develops his solutions. He then places another piece of paper, perhaps vellum, tracing paper, graphics 360, etc. on top of the line drawing and uses it as a reference for his design explorations. Underlays also serve to eliminate the need for the designer to redefine the perspective, scale, and proportions that are more easily tackled by using an underlay. This is only a tool used by designers to speed up their process. Once the sketches and simple shading are completed the designer can then take the newly defined concept and add some color so that they are more easily read by those that aren't as visually enabled as the designer.

Once the sketches and simple shading are completed the designer can then take the newly defined concept and add some color so that they are more easily read by those that aren't as visually enabled as the designer.

Thursday, May 7, 2009

Ahh! Ideation sketches and Design Process. Just what we like to see!

This project was undertaken by Zach while in College at The Massachusetts College of Art and Design in Boston Massachusetts. The project, as it reads, was presented as a branding exercise. Where Zach was to develop the branding for a hand held vacuum for the cordless power tool market. The brand that was selected was DeWalt.

This project was undertaken by Zach while in College at The Massachusetts College of Art and Design in Boston Massachusetts. The project, as it reads, was presented as a branding exercise. Where Zach was to develop the branding for a hand held vacuum for the cordless power tool market. The brand that was selected was DeWalt. A term that is used to describe brand identity in terms of its physical manifestation, is its Form Language. The form language of a brand, as it pertains to Brand Identity, are the physical embodiments that a family of products has established across all of its product offerings. Color, something a majority of consumers use to initially identify one brand or product offering from another, is very often used by a company to establish the initial visual relationship a consumer has with their product. I could delve into Color Psychology and how color can have a very strong affect on a consumers decision making process, but I will leave that for another article. Though I did want to make you aware that color is a strongly held consideration of Brand Identity.

A term that is used to describe brand identity in terms of its physical manifestation, is its Form Language. The form language of a brand, as it pertains to Brand Identity, are the physical embodiments that a family of products has established across all of its product offerings. Color, something a majority of consumers use to initially identify one brand or product offering from another, is very often used by a company to establish the initial visual relationship a consumer has with their product. I could delve into Color Psychology and how color can have a very strong affect on a consumers decision making process, but I will leave that for another article. Though I did want to make you aware that color is a strongly held consideration of Brand Identity. Case-in-point is the DeWalt Brand. The color combination of yellow/black is a very strong identifier for their brand, which they have Trademarked. Those that have seen the array of brands that are available within the power tool segment would not confuse Makita and DeWalt. Color is not the only Brand identifier. As I said the physical attributes are key to properly presenting the form language of a brand. And the logo isn't what I mean by physical embodiment. The physical attributes or characteristics of a product seek to inform you, the consumer, what features and benefits one solution offers over other options. Which are more often than not sitting right next to each other on the shelf. To keep with this specific example Zach has put together a set of detail images that illustrate exactly what I mean. He has tagged them Brand Identity and shows detailed images of how form language used in his design solution echos those of DeWalts existing products.

Case-in-point is the DeWalt Brand. The color combination of yellow/black is a very strong identifier for their brand, which they have Trademarked. Those that have seen the array of brands that are available within the power tool segment would not confuse Makita and DeWalt. Color is not the only Brand identifier. As I said the physical attributes are key to properly presenting the form language of a brand. And the logo isn't what I mean by physical embodiment. The physical attributes or characteristics of a product seek to inform you, the consumer, what features and benefits one solution offers over other options. Which are more often than not sitting right next to each other on the shelf. To keep with this specific example Zach has put together a set of detail images that illustrate exactly what I mean. He has tagged them Brand Identity and shows detailed images of how form language used in his design solution echos those of DeWalts existing products. In terms of research, Zach delved into both the DeWalt Brand and the hand held vacuum segment. Some of the questions he asked were. Who was already in the segment? What do those solutions do well? What do they do poorly? Price points and capabilities? Are they comfortable to hold and use? Do they cause undue stress or strain? What components are housed within the device? All of these factors, and many more, play a part in the development of a product. In an effort to truly understand the product he was developing Zach purchased a hand held vacuum and took it apart in order to understand what components he had to work with and how they might resolve some of the design consideration for him. Designers need to be aware of nearly every aspect of the product development cycle. The five W's (Who, What, When, Where, Why, and How) and everything else that comes along with those questions.

In terms of research, Zach delved into both the DeWalt Brand and the hand held vacuum segment. Some of the questions he asked were. Who was already in the segment? What do those solutions do well? What do they do poorly? Price points and capabilities? Are they comfortable to hold and use? Do they cause undue stress or strain? What components are housed within the device? All of these factors, and many more, play a part in the development of a product. In an effort to truly understand the product he was developing Zach purchased a hand held vacuum and took it apart in order to understand what components he had to work with and how they might resolve some of the design consideration for him. Designers need to be aware of nearly every aspect of the product development cycle. The five W's (Who, What, When, Where, Why, and How) and everything else that comes along with those questions. The final solution is the physical representation of all of the research, testing, engineering, and other discoveries that occur during the product development process. In the final model shown above, Zach has used the tools and materials available to him in order to accurately present his design concept in the most faithful way possible. A prototype is neither an example of how the item will be manufactured nor an example of the specific materials that the actual product will be manufactured with. The final solution is a consideration of the needs of the market. The cost of the item as it relates to production and the value the consumer places upon it, amongst other considerations. If the market place is already saturated by hand held vacuums for the cordless power tool segment. Then the target consumer is less likely to make a purchase, which renders the entire exercise an adventure in R&D and not a profitable one that most companies are likely to endeavor upon.

The final solution is the physical representation of all of the research, testing, engineering, and other discoveries that occur during the product development process. In the final model shown above, Zach has used the tools and materials available to him in order to accurately present his design concept in the most faithful way possible. A prototype is neither an example of how the item will be manufactured nor an example of the specific materials that the actual product will be manufactured with. The final solution is a consideration of the needs of the market. The cost of the item as it relates to production and the value the consumer places upon it, amongst other considerations. If the market place is already saturated by hand held vacuums for the cordless power tool segment. Then the target consumer is less likely to make a purchase, which renders the entire exercise an adventure in R&D and not a profitable one that most companies are likely to endeavor upon.Wednesday, April 29, 2009

Which Prototyping Method Should I Use & What's The Difference?

The word “prototype” comes from the Greek, protos meaning “first” and typos meaning “impression.” Like many words, its meaning has changed over time, so that a single finished product can be preceded by a number of “first impressions.” And while we’re often told the importance of making a great first impression, not all prototypes need to be great; some need only be adequate for a specific task. (Of course before committing to production, you might want at least one great first impression.)

Prototype plastic parts serve a variety of purposes. They can be used to test:

Form: Appearance, including overall shape, surface texture, and color.

Fit: The ability to interconnect with other parts of an assembly.

Function: The ability to withstand various kinds of stress under varying conditions, such as mechanical fatigue, heat, radiation or chemicals.

Manufacturability: The ability to be made using standard high volume production methods such as machining or injection molding.

Viability: The ability to appeal to the market. This means getting a production equivalent part into the hands of the consumer for testing. Because product development is an iterative process, it can include multiple prototyping steps, each serving a different function.

Because product development is an iterative process, it can include multiple prototyping steps, each serving a different function.

Virtual prototyping is supported by advanced 3D CAD software and actually produces a simulation of the part being designed. It is ideal for early conceptualization.

Pros: It allows parts to be designed, revised, virtually fitted together, and tested under simulated stress using finite element analysis. It lets a designer create and revise a design in real time at no cost except that of the software.

Cons: It is entirely digital, so going directly to high volume production from this point is very risky.

2. Stereolithography Apparatus (SLA)

SLA is an additive process that uses a computer controlled laser to cure layers of photopolymer resin. The process is suitable for making concept models or prototypes to support presentations or trade shows.

Pros: The process is a relatively inexpensive and fast way to make a single part, produces a good surface finish, and can reproduce very complex (even unmanufacturable) geometries. It is a good choice for testing the form and fit of a part.

Cons: It only works with a very limited range of proprietary resins and produces a fragile end product whose dimensional stability suffers over time.

3. Selective Laser Sintering (SLS)

SLS uses a computer-controlled laser to fuse powdered material. As is the case with SLA, SLS is suitable for making initial prototypes for demonstration purposes.

Pros: The process is relatively quick and inexpensive, produces more durable parts than SLA, and can also reproduce very complex geometries. It is a good choice to test form, fit and, to some extent, function.

Cons: It works with a very a limited range of materials, and the resulting parts have a rough finish. Although the parts tend to be more durable than those made using SLA, they are weaker than injection molded or machined parts. For these reasons it is not a good choice to test manufacturability or viability.

4. Fused Deposition Modeling (FDM)

FDM uses a thermal print head to deposit and fuse layers of resin. The process can produce both demonstration parts as well as low volume production parts for some applications.

Pros: It is a relatively inexpensive way to make prototype parts that are stronger than either SLA or SLS, and can also produce very complex geometries. It can be a good choice for testing form, fit and sometimes function. The material properties are better than SLA or SLS.

Cons: The process is much slower than the other additive processes and suffers from the same stair-stepped surface finishes (although this can be addressed to some extent with post-processing). It also only works with a small number of proprietary materials and cannot produce parts with the standard mechanical properties of CNC machined or injection molded parts. It is usually not a good choice for testing, manufacturability or viability.

5. Three Dimensional Printing (3DP)

3DP uses a print head to lay down a plaster-like material. As is the case with SLA, it is well suited for producing conceptual models during the early stages of design.

Pros: This is the fastest and least expensive of the additive processes. It allows the production of colored models and is ideal for testing form.

Cons: Parts have a rough surface finish and are very fragile. The material choices are even more limited than with other additive processes, and for these reasons it is not a good choice for testing fit, function, manufacturability or viability.

PJET is similar to SLA, using computer controlled UV light to cure layers of photopolymer. As is the case with SLA, PJET is used primarily as a concept modeling process.

Pros: The process offers the same advantages of SLA, but the process is less expensive to operate and is more office-friendly.

Cons: It has the same disadvantages as SLA, and is much more limited in the size of parts that can be made.

CNC machining uses standard computer controlled equipment to cut parts from a solid block of material. With the advent of First Cut’s automated toolpath generation technology, the process is useful for demonstration parts through low volume production.

Pros: It is as fast as the additive processes, and because it uses standard materials as feedstock it produces parts comparable to injection molding. For these reasons the process is a good choice for testing form, fit, function and viability.

Cons: The process is generally not well suited for production quantities in excess of hundreds of parts (see rapid injection molding).

8. Rapid Injection Molding (RIM)

RIM involves the use of proprietary software to automate the process of quoting, designing and manufacturing injection molds. It is useful in the production of small to medium quantities of parts for testing or bridge tooling prior to production.

Pros: RIM produces real injection molded parts in as little as one business day at a fraction of the cost of conventional injection molding. The parts are ideal for testing function, manufacturability and viability.

Cons: The non-recurring cost to manufacture the mold can make this process more expensive than additive prototyping processes for low volumes.

For a free, detailed report on prototyping processes, including detailed information on material strengths, surface finishes and process selection, visit their web site.

Monday, April 27, 2009

Inspirational Image Of The Day - Daniel Schumpert

Daniel Schumpert is a digital artist whose images have inspired me to get a Wacom tablet and dive into digital painting. I have to admit that when I look at this image all I see is Ayrton Senna and the days I would spend watching and learning about F1 from my brother. Daniel's image is an excellent exploration into the possibilities of digital art in the future.

Daniel Schumpert is a digital artist whose images have inspired me to get a Wacom tablet and dive into digital painting. I have to admit that when I look at this image all I see is Ayrton Senna and the days I would spend watching and learning about F1 from my brother. Daniel's image is an excellent exploration into the possibilities of digital art in the future.Concept Development & Exploration

While others use a digital medium to both explore and refine the forms they are developing. All are fine examples of concept exploration and you should use the method you prefer. Most importantly you should not let the tool get in the way of your process. If you are new to the digital medium, perhaps you should stick with the tried and true method you are familiar with until you feel more comfortable.

While others use a digital medium to both explore and refine the forms they are developing. All are fine examples of concept exploration and you should use the method you prefer. Most importantly you should not let the tool get in the way of your process. If you are new to the digital medium, perhaps you should stick with the tried and true method you are familiar with until you feel more comfortable. At the end of the day concept exploration is about ideas, not about presentation. Although you want to ensure that the design intent is maintained so you should make the effort to deliver clear sketches that fully convey your thoughts. Elements such as arrows and call outs help in this endeavor.

At the end of the day concept exploration is about ideas, not about presentation. Although you want to ensure that the design intent is maintained so you should make the effort to deliver clear sketches that fully convey your thoughts. Elements such as arrows and call outs help in this endeavor.

Saturday, April 25, 2009

Hyper-Realistic Rendering

Russ Schwenkler of Dangeruss is a world class digital modeler and 2d graphic artist, referred to as a Vexel artist. If you want to know what the definition of Vexel art is then head over to his site and read his about section.

Russ Schwenkler of Dangeruss is a world class digital modeler and 2d graphic artist, referred to as a Vexel artist. If you want to know what the definition of Vexel art is then head over to his site and read his about section.

Nike FeelFree - Headset for Relaxation. Identification, Ideation, and Solution.

Hannes Seeberg of Provoke Design in Tallinn, Estonia doesn't begin the design process with the design aesthetic and functional requirements all worked out in his mind. He allows the process of discovery to determine the needs that he must meet in the final solution. It didn't begin with perfect sketches or all of the necessary research laid out on a breadcrumb laden path either.

Hannes Seeberg of Provoke Design in Tallinn, Estonia doesn't begin the design process with the design aesthetic and functional requirements all worked out in his mind. He allows the process of discovery to determine the needs that he must meet in the final solution. It didn't begin with perfect sketches or all of the necessary research laid out on a breadcrumb laden path either. Hannes began by identifying a problem that affects 15% of the worlds population, which is depression. And 80% of these 15% are not undertaking any medical or psychological assistance. According to Hannes research, depression will be the second largest killer after Heart Disease by 2020.

Hannes began by identifying a problem that affects 15% of the worlds population, which is depression. And 80% of these 15% are not undertaking any medical or psychological assistance. According to Hannes research, depression will be the second largest killer after Heart Disease by 2020. Aside from the statistics and percentages he then began to research how the mental health of those affected by depression are currently being treated and how he may be able to present a new method of treatment utilizing sound. In the interest of moving forward and allowing the research Hannes conducted to speak for itself. I will move on to presenting Hannes ideation process and look at his sketches so that we are able to discover how Hannes thinks on paper.

Aside from the statistics and percentages he then began to research how the mental health of those affected by depression are currently being treated and how he may be able to present a new method of treatment utilizing sound. In the interest of moving forward and allowing the research Hannes conducted to speak for itself. I will move on to presenting Hannes ideation process and look at his sketches so that we are able to discover how Hannes thinks on paper.

In this initial set of sketches you can clearly see into Hannes thought process. His preliminary sketches present us with a form language for the speaker area of the headphones that is similar to what we are already familiar with seeing. Hannes is aware that he isn't developing a solution for listening to traditional music as we know it. And thus his solution shouldn't look like what we are traditionally accustomed to seeing.

He is developing a solution "that uses advanced technology to read brain frequencies and change it toward the applied stimulus without having a side affect on the users hearing." As this sketch page develops, Hannes is moving away from what tradition has taught him. He is now beginning to explore alternative methods of sound delivery. This is most clearly illustrated in the last sketch on the page above, which in profile presents itself as an S shape. (lower right)

In this initial set of sketches you can clearly see into Hannes thought process. His preliminary sketches present us with a form language for the speaker area of the headphones that is similar to what we are already familiar with seeing. Hannes is aware that he isn't developing a solution for listening to traditional music as we know it. And thus his solution shouldn't look like what we are traditionally accustomed to seeing.

He is developing a solution "that uses advanced technology to read brain frequencies and change it toward the applied stimulus without having a side affect on the users hearing." As this sketch page develops, Hannes is moving away from what tradition has taught him. He is now beginning to explore alternative methods of sound delivery. This is most clearly illustrated in the last sketch on the page above, which in profile presents itself as an S shape. (lower right) Now that Hannes has broken from tradition and is developing a concept that considers how sound is presented to the user. He is tasked with developing a pair of headphones that align with the aesthetic, functional, and performance minded values that the Nike brand encompasses. And in order to do this accurately, he must research the Nike brand and discover the underlying styling ques that tie all of their products together within the product segment he is targeting.

Now that Hannes has broken from tradition and is developing a concept that considers how sound is presented to the user. He is tasked with developing a pair of headphones that align with the aesthetic, functional, and performance minded values that the Nike brand encompasses. And in order to do this accurately, he must research the Nike brand and discover the underlying styling ques that tie all of their products together within the product segment he is targeting. As we see his, around the ear, concept develop we begin to see the lines of his sketches take on a more precise and intentional path. The curvilinear shapes begin to develop and take on a personality of their own and and breakaway form the rectilinear forms he was developing earlier. As he proceeds to develop the personality of his concept we see a more evident direction come into focus. A solution that is symmetrically balanced and uses a curvilinear silhouette to garner the attention of the user. Indicating that these aren't headphones solely designed for reproducing the whales of your favorite artist!

As we see his, around the ear, concept develop we begin to see the lines of his sketches take on a more precise and intentional path. The curvilinear shapes begin to develop and take on a personality of their own and and breakaway form the rectilinear forms he was developing earlier. As he proceeds to develop the personality of his concept we see a more evident direction come into focus. A solution that is symmetrically balanced and uses a curvilinear silhouette to garner the attention of the user. Indicating that these aren't headphones solely designed for reproducing the whales of your favorite artist!

He has accomplished this while also accurately conveying the excitement, personality, and dependability of the Nike brand.

He has accomplished this while also accurately conveying the excitement, personality, and dependability of the Nike brand.

Thursday, April 23, 2009

Why and How to convey moving parts in a sketch.

Adding arrows is an excellent technique that designers use to illustrate the functionality of a design. Andres has done a fine job of presenting the functionality of this sketch table by keeping the lines of the table clean. Allowing the viewer to focus on both the design of the table and on its functionality. He has used arrows to convey that the drawing surface rotates, the drawers flip out, and that the desk can adjust in width to suit the user. Lightly coloring the arrows conveys that the designer considered both the design and functionality of the concept. Andres also grounded the sketch by using a block of color behind the sketch, which adds depth and visual weight to the composition. This technique also adds another layer of consideration that clients enjoy seeing.

Adding arrows is an excellent technique that designers use to illustrate the functionality of a design. Andres has done a fine job of presenting the functionality of this sketch table by keeping the lines of the table clean. Allowing the viewer to focus on both the design of the table and on its functionality. He has used arrows to convey that the drawing surface rotates, the drawers flip out, and that the desk can adjust in width to suit the user. Lightly coloring the arrows conveys that the designer considered both the design and functionality of the concept. Andres also grounded the sketch by using a block of color behind the sketch, which adds depth and visual weight to the composition. This technique also adds another layer of consideration that clients enjoy seeing.

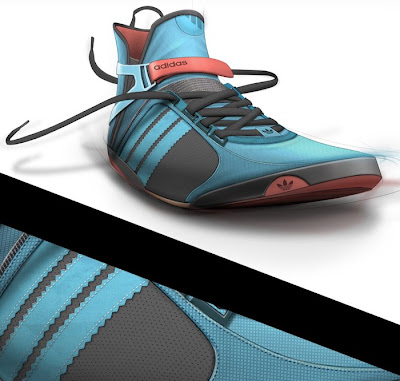

Shoe Concept - Adidas

Nicolas has gone to great lengths to consider the composition of this sketch. The very expressive and lively posture of the shoe and the laces really express the personality of the shoe and the person who would wear it. The Velcro strap and finger loop on the back of the shoe really convey how simply it will be to slip these shoes on. Another very evident aspect of the design of these shoes and the way they are presented is that these shoes don't take themselves to seriously and are socially disarming in today's generation. Like Andres, Nicolas has considered the assembly of the shoe and how he can use the stitches as part of the design. In the lower half of the image you can see a glimpse of the details he considered when designing this shoe. The texture really adds another layer of complexity and refinement to the design. Something that can easily be overdone and should be carefully weighed before laying down your final thoughts.

Nicolas has gone to great lengths to consider the composition of this sketch. The very expressive and lively posture of the shoe and the laces really express the personality of the shoe and the person who would wear it. The Velcro strap and finger loop on the back of the shoe really convey how simply it will be to slip these shoes on. Another very evident aspect of the design of these shoes and the way they are presented is that these shoes don't take themselves to seriously and are socially disarming in today's generation. Like Andres, Nicolas has considered the assembly of the shoe and how he can use the stitches as part of the design. In the lower half of the image you can see a glimpse of the details he considered when designing this shoe. The texture really adds another layer of complexity and refinement to the design. Something that can easily be overdone and should be carefully weighed before laying down your final thoughts.